News: VIA Material wins Gold...

...for its recycled terrazzo at the German Design Award 2025

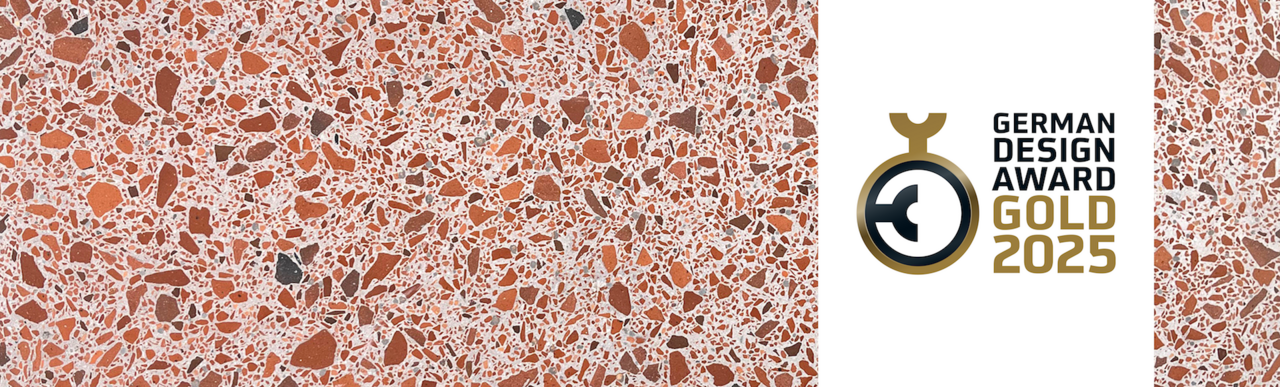

VIA Material is one of the winners of the German Design Award 2025. The gold award for the recycled terrazzo launched in 2024 in the "Excellent Product Design - Building and Elements" category emphasises the outstanding design quality of the product. An international jury of experts also selected the product for its pioneering role in the construction industry.

Recyclingterrazzo

Terrazzo floors with recycled material

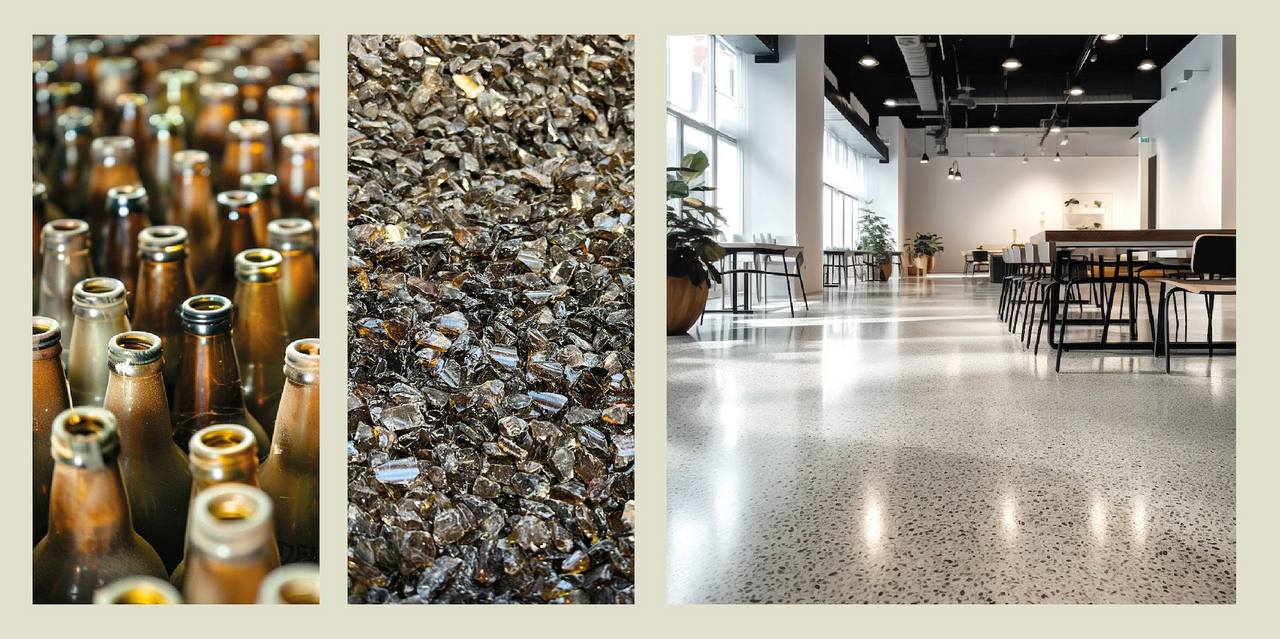

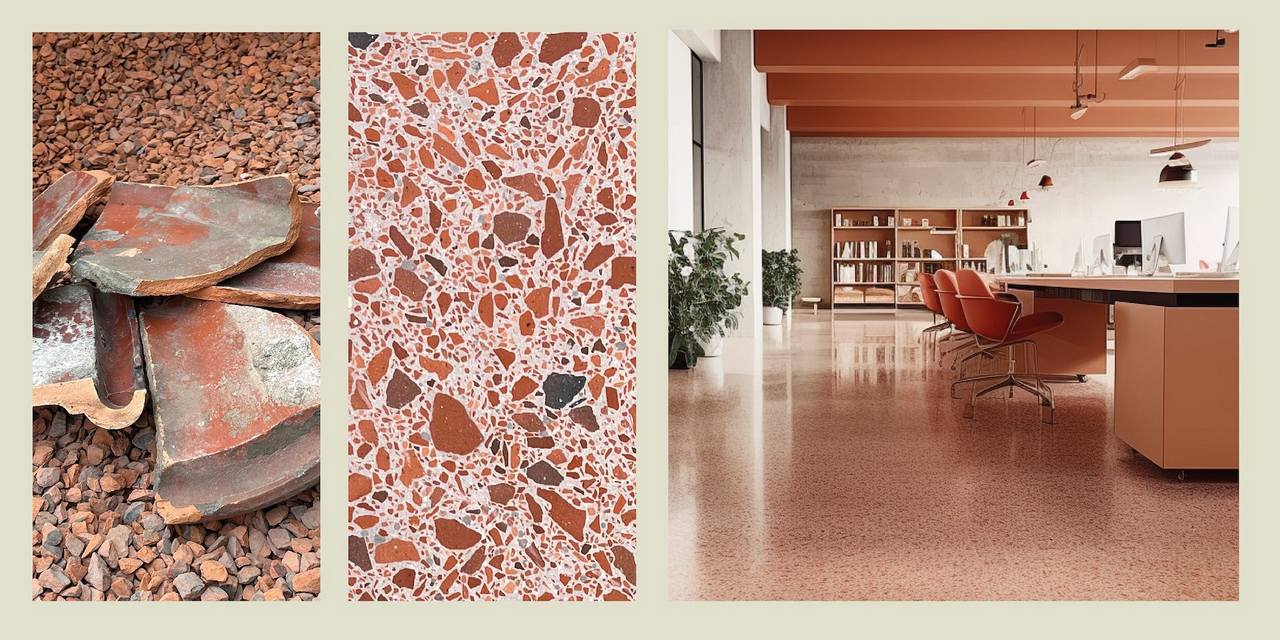

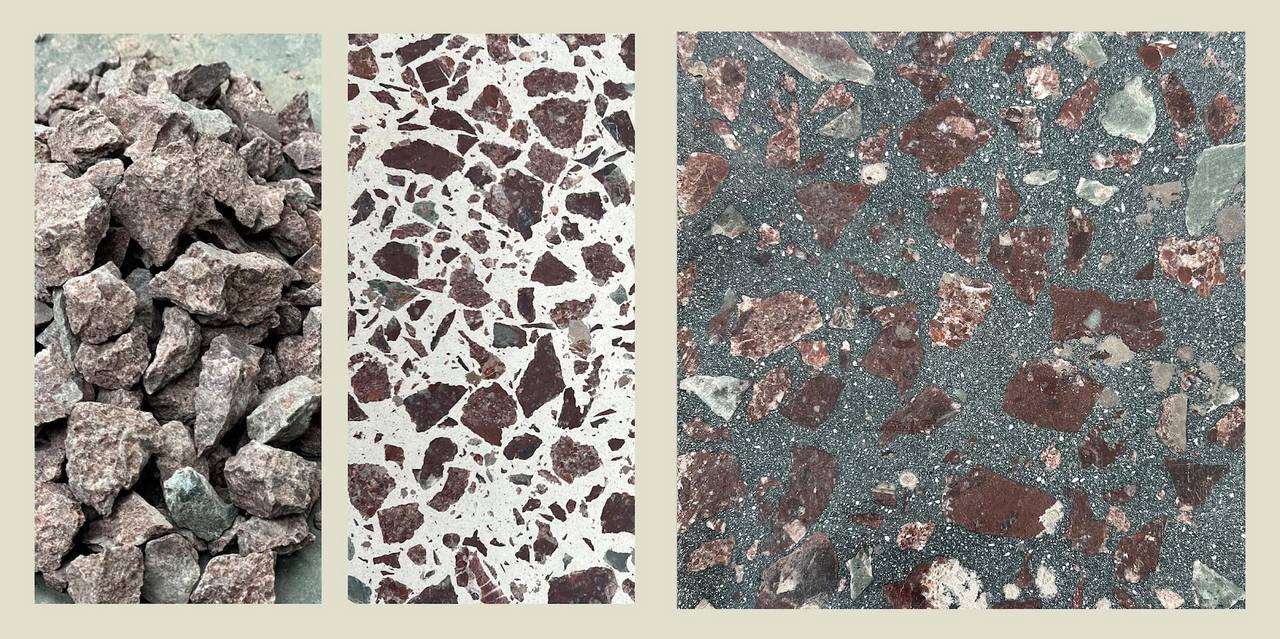

With its terrazzo, VIA is able to process a wide range of materials from building material recycling and realise architectural ideas. VIA first produces samples from the demolition material. Once the recipe has been determined, the processed building material can be used to produce customised recycled terrazzo. VIA supplies you with everything except the recycled aggregate and water.

VIA terrazzo is already characterised by being 100% recyclable and free of cement and epoxy resin. By using materials from deconstruction, VIA can now create customised floors that have a positive effect on the construction sector and therefore make builders and planners doubly happy.

Roof tiles are characterised by the fact that they are very hard and have low water absorption. Create an environmentally friendly, stylish and durable floor that is also easy to maintain with VIA roof tile terrazzo. Instead of stone chips, the brick is crushed and added to the terrazzo mix and processed.

The bricks for this terrazzo were sent by a customer from a demolition project. VIA crushed the bricks with a jaw crusher. Depending on the set grading curve, aggregates are obtained in the desired sizes and a terrazzo sample panel of the VIA brick terrazzo is produced.

VIA recycled terrazzo combines sustainability with timeless elegance and is therefore an excellent option for all architects, designers and builders looking for stylish as well as environmentally conscious and practical solutions.

VIA Terrazzo is already characterized by being 100% recyclable and free from cement and epoxy resin.

Terrazzo with recycled aggregates offers numerous ecological and economic benefits:

Ecological Benefits

• Resource conservation: Reuse of demolition material reduces the need for new primary raw materials. Up to 60% of Recycling Terrazzo consists of recycled material.

• Waste reduction: Old building materials are put to meaningful use instead of ending up in landfills.

• CO₂ savings: Reduced energy consumption for extraction, transport, and processing of primary materials.

• Circular economy: Promotes sustainable construction and the reuse of building materials.

Economic Benefits

• Lower material costs: Demolition material is often less expensive than newly extracted aggregates.

• Value creation from old materials: Existing resources are reused instead of being disposed of.

• Possible subsidies: In many countries, there are financial incentives for sustainable construction.

Aesthetic Aspects

• Unique appearance: Recycled aggregates create individual color and texture patterns.

• High durability: The density and careful selection of aggregates result in robust and hard-wearing surfaces. Thanks to the purely mineral binding system based on environmentally friendly water glass, VIA Terrazzo is extremely low-tension and therefore free from cracking.

• Versatile combinations: A wide variety of material combinations are possible.

For use as an aggregate in Recycling Terrazzo, the material should be crushed to a grain size of 0–10 mm.

This fraction is ideal for a homogeneous mix and an aesthetically appealing surface.

The ratio depends on the composition of the Recycling Terrazzo. Typically, between 50% and 60% of the mix can consist of recycled material, depending on the desired appearance, strength, and workability.

Common sources include old concrete or natural stone debris, which are combined with the VIA mineral binder (cement- and epoxy-free) and water.

Recycling Terrazzo can sometimes be less expensive since the raw material (e.g., demolition debris) is already available. However, costs also arise from sorting, cleaning, and processing the material.

Overall, pricing depends on the availability, transport, and processing of the recycled material. Where local material sources are available, Recycling Terrazzo can be a particularly cost-effective solution.

The demolition material must be carefully sorted on site to avoid contamination (e.g., gypsum, wood, or metals). Key requirements:

• Material type: Concrete, brick, tiles, or glass, as well as marble, granite, or other natural stones.

• Condition: Free from pollutants, paint, coatings, or organic residues.

• Grain structure: For an appealing terrazzo surface, the material should be evenly broken down to the right size fraction.

Sorting is usually carried out directly on site, either manually or with crushing plants equipped with screening systems.

On-site processing

If possible, the material can be crushed and prepared directly on site.

Process steps

1. Crushing with jaw or roller crusher

• Adjust crusher settings so that the final material falls within the desired maximum grain size.

• If necessary, use an additional fine crusher or screening system to remove oversize material.

• Remove foreign substances (reinforcement, plastics, wood) before crushing.

• A magnetic separator can be used to eliminate remaining steel or metals.

• End fraction: 0–10 mm recycled aggregate.

2. Packaging in big bags

• Fill recycled aggregate into big bags (1 m³ or 1.5 m³) with a load capacity of at least 1 tonne.

• Use big bags with an inner liner (e.g., polyethylene foil) to protect against moisture.

• Label bags clearly: grain size (e.g., 0–10 mm), filling date, intended use (Recycling Terrazzo aggregate).

• Place on pallets for easier handling and transport.

3. Transport

• For large volumes: send to specialized recycling facilities for further processing.

• For nearby projects: direct reuse is possible, avoiding long transport distances and extra costs.

Beate Brockamp

? brockamp@viamaterial.de

Customised floors made from local stone

Why go far afield... Local terrazzo floors are made from stone quarried in the immediate vicinity of the construction site. This creates a direct link to the region and enables a unique design that is harmonised with the surroundings. Do you have a quarry in your region? Or a stone aggregate that you would like to use in your terrazzo floor? This is possible with VIA.

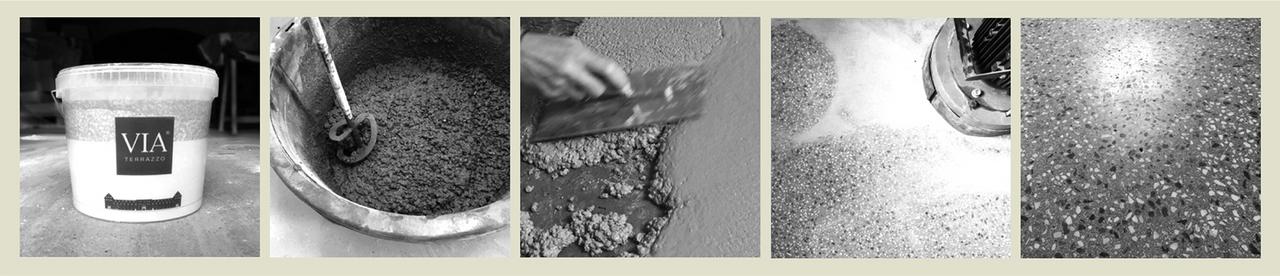

The terrazzo mixture is mixed with water in buckets and levelled directly trowel by trowel. The VIA binder allows dry sanding the very next day, which has several advantages:

- No additional moisture input

- Simple and clean work thanks to effective extraction technology

- The sanding dust can be easily disposed of.

Finally, the sanded and clean floor is impregnated with VIA Mineral Impregnation. The VIA terrazzo floor is ready after a few days - with a low installation height from 0.7 cm. VIA terrazzo is cured by crystallisation, so the material does not shrink.

![[Translate to Englisch:] Maschine für die Zerkleinerung von Gesteinsbrocken, Backenbrecher](/fileadmin/_processed_/b/2/csm_Backenbrecher_Copyright_bauforum24.biz_8b2fe23cc1.jpg)

What project are you currently planning?

Do you also have a raw material that you would like to reuse?

Contact us and we will create your personalised VIA recycled terrazzo mix.

Contact: Beate Brockamp

brockamp@viamaterial.de

VIA Terrazzo

Ecological. Robust. Beautiful.

• Fast and practical processing

• Ready-mix in a bucket

• Low installation height

• 100 % recyclable

• Customised mixtures possible

• Free of cement and epoxy resin

• Fire protection class A1

• Durable and easy to clean

VIA Terrazzo is designed to meet the demands of modern construction and renovation projects. It is practical and quick to work with and can be ideally integrated into all projects.

![[Translate to Englisch:] Bilderreihe mit grünen Altglasflaschen, Glassplitt und Terrazzo mit Glassplitt grün](/fileadmin/_processed_/6/f/csm_Composing_Terrazzo_Recycling_Gruenglas_01_454cdeb688.jpg)